Surface treatment: Spraying, oil Spraying, electroplating, electrolysis, hot dip zinc, oxidation, spray painting, polishing, drawing, screen printing and so on.Our existing powder spraying production line, the product after 9 pre-treatment processes such as rust removal, pickling, phosphating into the spray room Electrostatic Spraying, and then after 200 degrees of high temperature to melt the powder adsorbed on the surface of the product, in order to achieve rust prevention, corrosion prevention, beautiful and other effects.Other outsourcing processing is required. Although it is outsourced processing, it does not affect the quality and delivery time of our products.Spraying processing is an indispensable and important process for Dongji sheet metal processing and sheet metal factory. The equipment of sheet metal factory has very high quality requirements for sheet metal products.

Surface treatment technology

Surface treatment is the process of artificially forming a surface layer with different mechanical, physical and chemical properties on the surface of the basic material.The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration and other special functions.For metal castings, the most commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, spraying surface treatment, surface treatment is to the workpiece surface cleaning, cleaning, deburring, degreasing, scaling and so on.

Material

* Iron, stainless steel, galvanized sheet, electrolytic sheet, aluminum

* 0.2 - 30.0 mm thickness

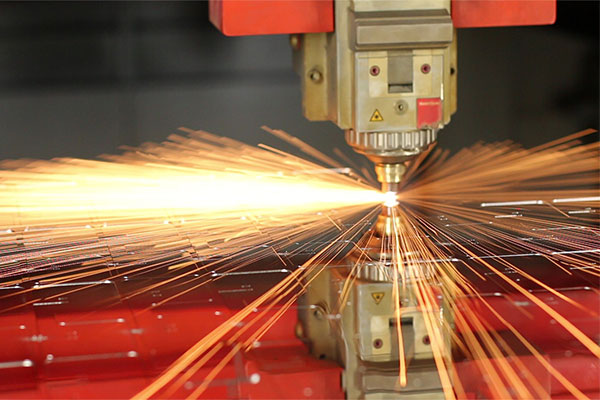

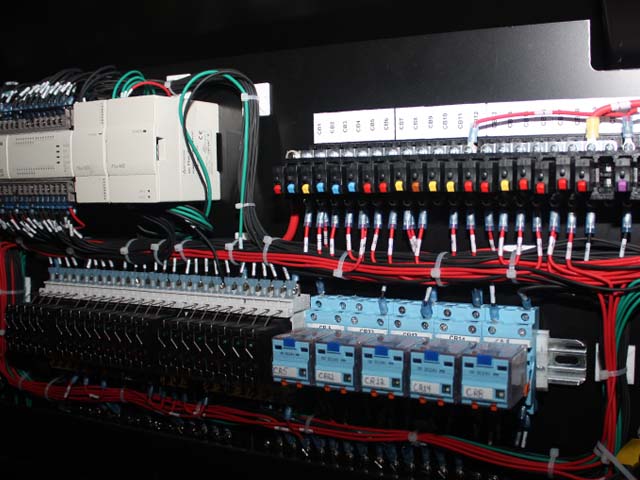

Production equipment

After treatment processes such as rust removal, pickling, phosphating, etc., the products are put into the spray booth for Electrostatic Spraying, and then the powder is melted and adsorbed on the product surface at a high temperature of 200 degrees to achieve the effect of rust prevention.

Powder Coating Line

Quantity:2 pc

· Compliance with environmental standards

· Gema Automatic powder coat assembly line

· Corrosion-resistant and wear-resistant, more than 5 years of quality assurance