Designing, Processing, Assembling one-stop Service

We own professional team and advanced automatic production lines

to provide you the high quality and efficient services.

0+

Region Country

0m²

Plant Area

0+

Staff

0+

Production Line

The technical team is composed of personnel with more than 10 years of experience, and constantly improves the level of technology

Mature production management system can quickly coordinate resources, reject production delays, and estimate accurate delivery dates for you

As long as you provide actual samples or drawings, you can customize processing, surface treatment and assembly according to your needs

Respond immediately if you have any questions, do not shirk in case of trouble, and provide you with a comprehensive and efficient service with a professional attitude and knowledge

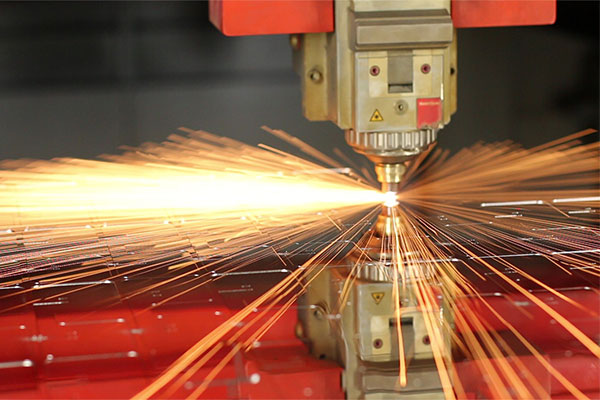

Laser cutting technology is widely used in the processing of metal and non-metal materials, which can greatly reduce the processing time, reduce the processing cost and improve the quality of the workpiece.The modern laser has become the “sword” of people's fantasy pursuit of “cutting iron like mud”.Laser cutting is an indispensable equipment in sheet metal processing, and is the most representative procedure in sheet metal processing industry.Dongji sheet metal is a large laser cutting processing plant from Jiangmen area, with 3 large-power laser cutting machines in Jiangmen, specializing in laser cutting sheet metal processing.

Laser cutting technology is widely used in the processing of metal and non-metal materials, which can greatly reduce the processing time, reduce the processing cost and improve the quality of the workpiece.Laser cutting is realized by using the high power density energy generated by laser focusing.And controlled by computer, through the pulse laser discharge, thus the output controlled repeated high frequency pulse laser, the formation of a certain frequency, pulse width of the beam, the pulse laser beam through the light path transmission and reflection and through the focusing lens group focused on the machining surface, forming a subtle, high energy density, intensity, focal spot near to processing surface, with instantaneous high temperature melting or gasification materials processed.The modern laser has become the “sword” of people's fantasy pursuit of “cutting iron like mud”.Laser cutting is an indispensable equipment in sheet metal processing, and is the most representative procedure in sheet metal processing industry.Dongji sheet metal is a large laser cutting processing plant from Jiangmen area, with 3 large-power laser cutting machines in Jiangmen, specializing in laser cutting sheet metal processing.

Each high energy laser pulse sputtered a small hole on the surface of the object in an instant. Under the control of the computer, the laser machining head and the processed material hit points in continuous relative motion according to the pre-drawn figure, so that the object can be processed into the desired shape.When cutting externally, a stream of gas coaxial with the beam is ejected from the cutting head and the melted or vaporized material is blown out from the bottom of the cut (note: if there is a thermal effect between the gas blown out and the material to be cut, the reaction will provide additional energy for cutting;The airflow also has the function of cooling the cut surface, reducing the heat affected area and keeping the focusing mirror free from contamination.Compared with the traditional plate processing method, laser cutting has the advantages of high cutting quality (narrow incision width, small heat affected area, smooth incision), high cutting speed, high flexibility (can cut any shape at will), wide material adaptability and so on.

Production equipment

Our company owns a Bystronic Di Neng 3000W laser cutting machine, which can cut medium and thick plates without using a mold, and can cut steel plates of any shape, with a smooth laser cutting surface.

Laser Cutting Machine

Quantity:3 pc

· Power 3000w

· Processing accuracy 0.1mm

· Processing speed 20 m/min

CNC punch machines not only provide unimaginable speed and accuracy, but also increase the ability of simple programming, crimping, deburring, and tapping.Create more parts in less time than traditional manufacturing or processing.For larger parts, nc stamping provides a minimum cycle time per piece.Increase our output to meet the needs of our customers.We invest in the latest equipment to ensure that we provide our customers with the best quality products at the lowest cost.

Progressive punching is a metalworking method that can involve stamping, manufacturing, bending and several other methods to modify the metal to produce the desired shape of the end part.Most of the materials are used, so less waste is produced.Progressive die metal stamping may provide the most cost-effective material choice to manufacture your parts.

Production equipment

Amada CNC puching machine from Japan,with curling, deburring, tapping and punching processing capabilities.

CNC Punching Machine

Quantity:1 pc

· Pressure 20 tons

· Processing accuracy 0.1mm

· Processing speed 800 times/min(Calculated on 1mm thickness)

Punching Machine

Quantity:4 pc

· Pressure 20 ~100tons

Numerical control bending processing advantages

CNC bending is formed by laser or CNC punching and other processed sheet materials through pressure and mold.The size and accuracy of bending are closely related to the type of material, thickness, coefficient, resilience and the use of the die.Our sheet metal factory undertake external processing, external CNC bending processing, Jiangmen large sheet metal factory, Jiangmen Sheet metal factory, Jiangmen sheet metal processing including CNC bending processing, CNC bending machine imported from Japan, and laser cutting machine, CNC punching machine, laser cutting processing.

Numerical control bending is different from ordinary bending

CNC bending machine and ordinary bending machine are made of stainless steel, ordinary steel plate and other plates.The difference is whether there is computer control and automatic feedback.The different results are: machining speed, machining precision and machining efficiency.

Numerical control bending principle

Plate bending is the process of changing the Angle of a plate or sheet.If bend the plate into V shape, U shape, etc.Generally speaking, sheet metal bending has two methods: one is mold bending, used for complex structure, small volume, large amount of processing of sheet metal structure;The other is bending with a bending machine, used for processing large or small size of the structure of the sheet metal structure.These two bending methods have their own principles, characteristics and applicability.

Production equipment

Trubend CNC Bending Machine

Using the Trubend 5130 automatic bending machine from Germany , combined with six-axis robot arm which can greatly reduce the labor intensity of workers, improve the working environment ,effective efficiency, product's quality and quality consistency at the same time .

Quantity:1 pc

· Pressure 100 tons

· Processing accuracy 0.1mm

· Processing area 0.3mm- 10mm

· Maximum process length 3.2 m

CNC Bending Machine

Using GHBM CNC bending machine, can process thinkness 0.2 to 22.0 mm of variety of metal plates. Including iron, stainless steel, galvanized steel, electrolytic plate, aluminum steel and cold-rolled plate and so on. High precision , fast speed and safety.

Quantity:12 pc

· Pressure 100 tons

· Processing accuracy 0.1mm

· Maximum process length 3.2 m

Welding is a machining or sculptural process in which materials(usually metal or thermoplastic)are joined together, as opposed to low-temperature metal joining techniques such as brazing and welding, which do not melt base metals.In addition to melting base metals, filler materials are usually added to the joints to form a weld pool(pool),which cools the pool to form a joint based on a welded structure (butt joint, full depth, rounded corners, etc.)that is stronger than the base metal (base metal).Pressure can also be used in conjunction with heat or alone to produce a weld.

Moreajor characteristic

High welding productivity;Good welding quality;Low welding cost;Good working conditions;Difficult space welding;High quality requirements for welding components;Not suitable for welding sheet metal(arc stability is poor when welding current is less than 100 A)and short welds.

Material

* Iron, stainless steel, galvanized sheet, electrolytic sheet, aluminum, etc.

* Thickness: 0.2-30.0mm.

Production equipment

Our company's existing 3 welding assembly lines. Including the ARC welding, carbon dioxide,deep throat clamp welding and laser welding sheet metal processing. Match the processing demand of different welding materials, with the advantage of high efficiency and strong finishing and reliable.

Welding Production Line

Quantity:3 pc

· Arc welding, carbon dioxide and laser welding,Robot welding

Surface treatment: spraying, oil spraying, electroplating, electrolysis, hot dip zinc, oxidation, spray painting, polishing, drawing, screen printing and so on.Our existing powder spraying production line, the product after 9 pre-treatment processes such as rust removal, pickling, phosphating into the spray room electrostatic spraying, and then after 200 degrees of high temperature to melt the powder adsorbed on the surface of the product, in order to achieve rust prevention, corrosion prevention, beautiful and other effects.Other outsourcing processing is required. Although it is outsourced processing, it does not affect the quality and delivery time of our products.Spraying processing is an indispensable and important process for Dongji sheet metal processing and sheet metal factory. The equipment of sheet metal factory has very high quality requirements for sheet metal products.

Surface treatment technology

Surface treatment is the process of artificially forming a surface layer with different mechanical, physical and chemical properties on the surface of the basic material.The purpose of surface treatment is to meet the requirements of corrosion resistance, wear resistance, decoration and other special functions.For metal castings, the most commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, spraying surface treatment, surface treatment is to the workpiece surface cleaning, cleaning, deburring, degreasing, scaling and so on.

Material

* Iron, stainless steel, galvanized sheet, electrolytic sheet, aluminum

* 0.2 - 30.0 mm thickness

Production equipment

After treatment processes such as rust removal, pickling, phosphating, etc., the products are put into the spray booth for electrostatic spraying, and then the powder is melted and adsorbed on the product surface at a high temperature of 200 degrees to achieve the effect of rust prevention.

Powder Coating Line

Quantity:2 pc

· Compliance with environmental standards

· Gema Automatic powder coat assembly line

· Corrosion-resistant and wear-resistant, more than 5 years of quality assurance

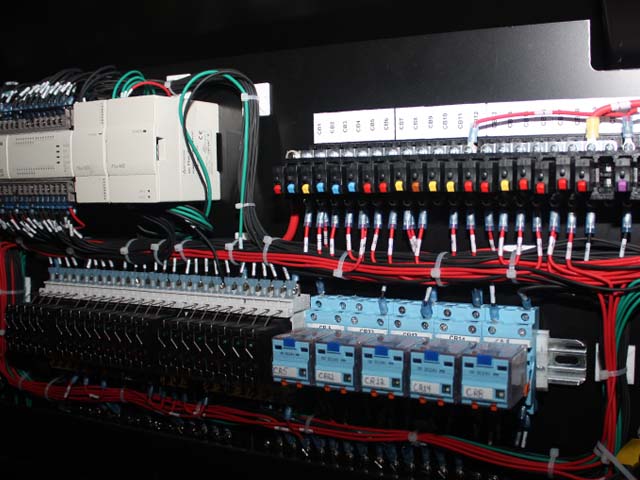

We own two electronic assembly lines, numbers of electronic technical engineers and testing engineers. They work equipped with high precision terminal crimping machine, can deal with the assembly and testing of various electrical parts with advantage of high efficiency and reliable quality.

Electronic Aassembly line

Quantity:2 pc

· High precision terminal crimping machine

· High efficiency, high quality

· Assembly of finished electrical parts