With the gradual acceleration of my country's socialization process, sheet metal processing products have penetrated into all walks of life. Compared with traditional parts and components, sheet metal parts have obvious advantages in strength, weight and cost. However, people have higher and higher quality and requirements for sheet metal accessories, so optimizing the process of sheet metal processing has become the research focus of the sheet metal industry. The optimization of Sheet metal processing generally starts from 4 basic links in processing.

1. Blanking link

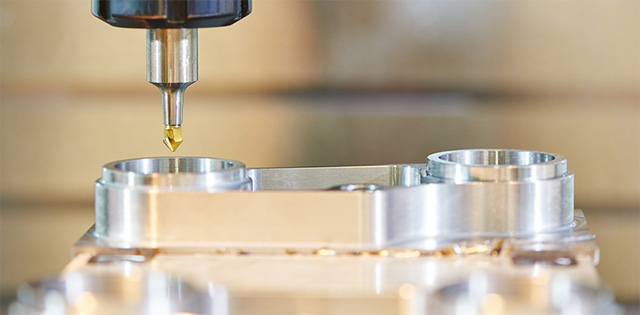

First of all, as far as the blanking link is concerned, under normal circumstances, blanking refers to the separation of the sheet metal materials through the punching of the mold, thereby achieving the separation of the sheet metal. This link is usually applied to the relative processing shape. Relatively simple Parts processing links, so as to achieve a higher degree of accuracy in processing shapes, while reducing material waste to a greater extent. In this link, the shape of the blanking sheet metal parts should be controlled first. In the corner areas of the outer and inner holes of the blanking and cutting, an arc should be set to overshoot the corners to avoid sharp angles and reduce the risk of follow-up. The problem of mold cracking caused by improper heat treatment will affect the subsequent sheet metal construction; then, the punching and its small value should be optimized.

2. Bending link

The bending link usually refers to the process of placing the sheet metal material on the bending equipment, the sheet metal material is elastically deformed by the pressure of the upper and lower molds, and plastic deformation occurs according to the actual design plan after the elastic deformation. In the application process of this link, different parts should be selected according to the actual design requirements to set the size, and the actual bending operation should be determined according to the thickness of the sheet metal material.

3. Press riveting link

The riveting process of sheet metal parts means that the sheet metal materials are deformed by pressure to couple them together. This process is usually used in screw riveting, bolt riveting, etc. As far as the riveting operation is concerned, the nut is usually round and has an embossed gear and wire notch. Therefore, the riveting process for sheet metal parts not only optimizes the quality of the original nut production process, but also avoids the welding work.

4. Welding link

The welding link is one of the important ways to connect the various parts of the structure in the cold working link of the entire Sheet metal processing process. Therefore, this link is usually placed in the background of high temperature for operation. At present, most of the common welding methods are carried out by argon arc welding, contact spot welding and other methods. Therefore, in the actual welding process, different welding methods should be selected according to the properties of different sheet metal parts, to a large extent, to ensure the reduction of welding deformation and improve the actual efficiency of welding.